Daga cikin duk hanyoyin tsaftacewa na yanzu, tsaftacewa na ultrasonic shine mafi inganci da inganci. Dalilin da ya sa ultrasonic tsaftacewa zai iya cimma irin wannan sakamako yana da alaƙa da ƙa'idar aiki ta musamman da hanyar tsaftacewa. Hannun tsaftace hannu na gama gari babu shakka ba za su iya biyan buƙatun ba. Ko da tsaftacewar tururi da tsaftataccen ruwa mai tsaftar ruwa ba zai iya biyan buƙatun tsafta mafi girma ba. Saboda haka, wannan shi ne dalilin da ya sa ultrasonic tsaftacewa da aka ƙara amfani a daban-daban masana'antu.

Yankunan aikace-aikacen ultrasonic tsaftacewa:

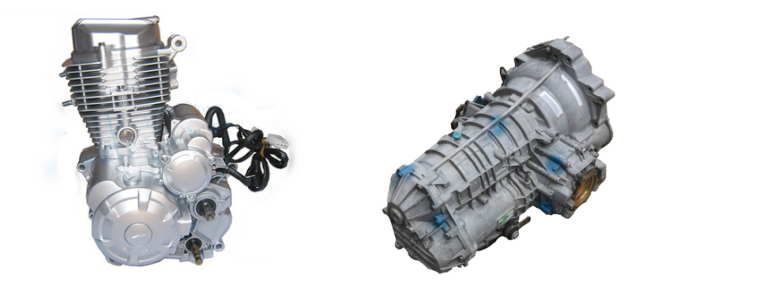

1. Masana'antar injina: kawar da mai mai hana tsatsa; tsaftace kayan aikin aunawa da kayan aikin yanke; degreasing da tsatsa kau na inji sassa; tsaftacewa na inji, carburetors da auto sassa, dredging da tsaftacewa na tacewa da fuska, da dai sauransu.

2. Surface jiyya masana'antu: degreasing da tsatsa cire kafin electroplating; tsaftacewa kafin ion plating; maganin phosphating; cire carbon adibas, oxide sikelin, polishing manna, surface kunnawa jiyya na karfe workpieces, da dai sauransu.

3. Masana'antar likitanci: tsaftacewa, tsaftacewa, lalata kayan aikin likita, tsaftace kayan aikin dakin gwaje-gwaje, da dai sauransu.

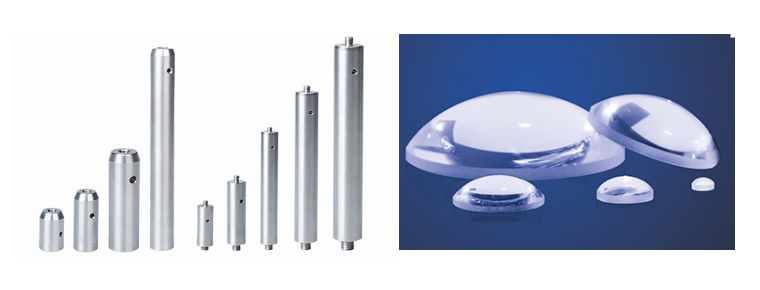

4. Instrumentation masana'antu: high tsabta tsaftacewa na daidaitattun sassa, tsaftacewa kafin taro, da dai sauransu.

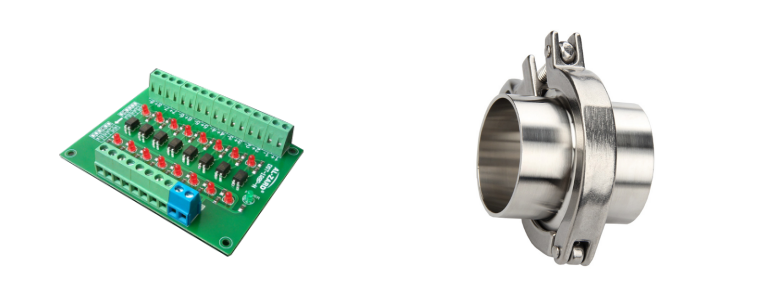

5. Electromechanical da lantarki masana'antu: kau da rosin da waldi spots a buga kewaye allon; tsaftacewa na high-voltage lambobi, tashoshi da sauran inji da lantarki sassa, da dai sauransu.

6. Masana'antu na gani: ragewa, gumi, cire ƙura da sauransu don na'urorin gani.

7. Semiconductor masana'antu: high tsabta tsaftacewa na semiconductor wafers.

8. Kimiyya, ilimi da al'adu: tsaftacewa da lalata kayan aikin dakin gwaje-gwaje kamar sunadarai da ilmin halitta.

9. Watches da kayan ado: cire sludge, kura, oxide Layer, polishing manna, da dai sauransu.

10. Petrochemical masana'antu: tsaftacewa da dredging na karfe tace; tsaftace kwantena sinadarai, masu musayar wuta, da sauransu.

11. Masana'antar bugu da rini: tsaftace kayan yadi, spinnerets, da sauransu.

12. Wasu: Ultrasonic tsaftacewa: cire pollutants, dredge kananan ramuka, kamar tsaftacewa like, tsoho maidowa, da kuma dredging na mota lantarki nozzles.

Ultrasonic stirring: bugun sama rushe, inganta uniformity, bugun sama jiki da kuma sinadaran halayen, hana kan-lalata, bugun man-ruwa emulsification, kamar sauran ƙarfi rini hadawa, ultrasonic phosphating, da dai sauransu.

Ultrasonic coagulation: accelerated hazo da rabuwa, kamar iri flotation, abin sha slag kau, da dai sauransu.

Haifuwar Ultrasonic: kashe ƙwayoyin cuta da gurɓataccen yanayi, kamar maganin najasa, zubar da ruwa, da sauransu.

Rarraba Ultrasonic: rage girman barbashi na solute, kamar rarrabuwar tantanin halitta, gwajin sinadarai, da sauransu.

Ultrasonic sealing: Kawar da interstitial gas da kuma ƙara gaba daya yawa, kamar tsoma fenti.

Lokacin aikawa: Juni-22-2021