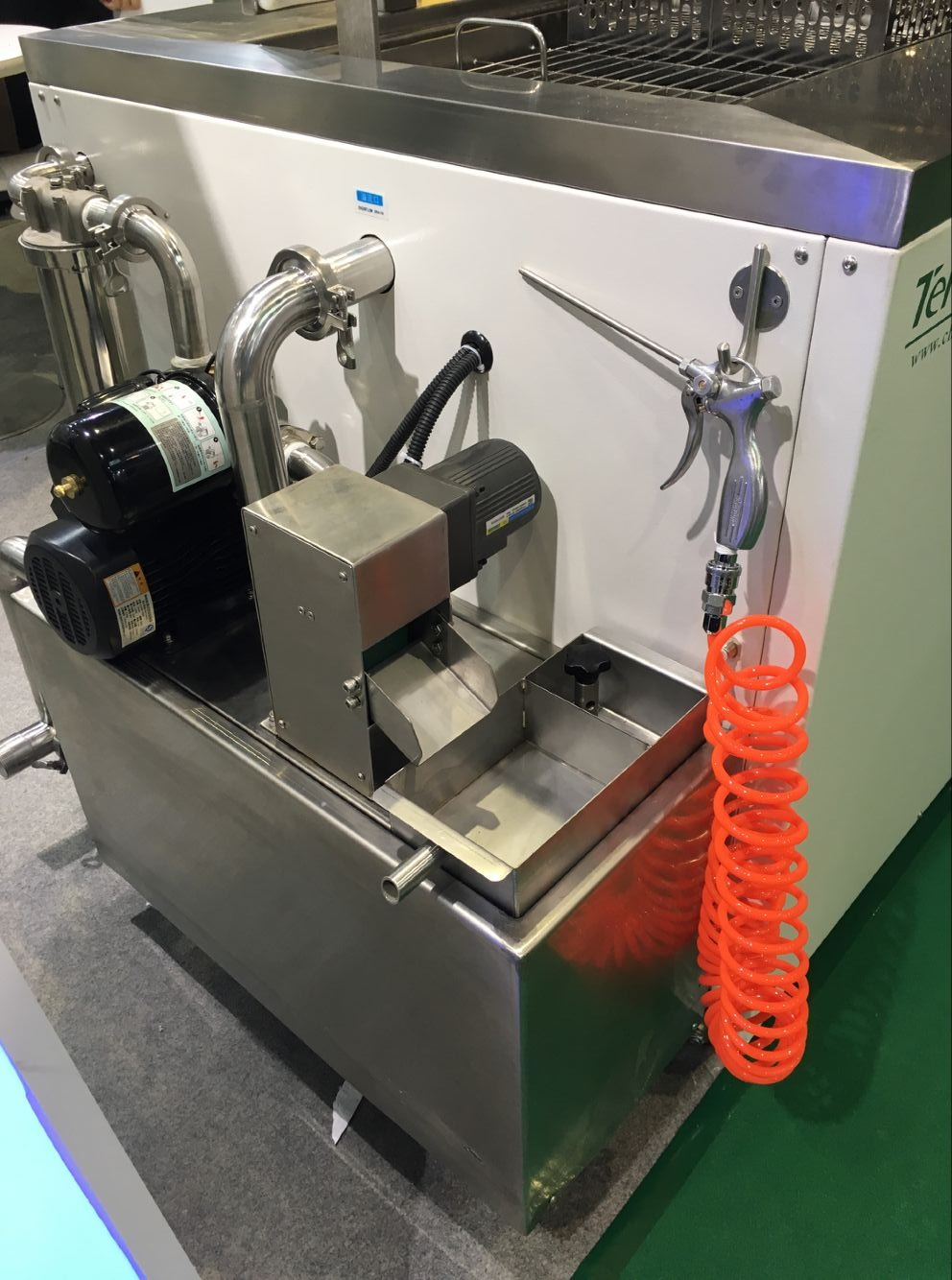

Ultrasonic cleaning machines are widely used in various industries, particularly in electronics, machinery, and medical fields. To ensure their stable performance and extend their service life, daily maintenance and care are crucial. Today, the editor from a Shanghai-based ultrasonic cleaning machine manufacturer will introduce how to properly maintain and care for ultrasonic cleaning machines, avoid common failures, and ensure the equipment's cleaning efficiency and safety.

Important Considerations for Using Ultrasonic Cleaning Machines

Prevent Circuit Damage from Moisture

The ultrasonic control cabinet is one of the core components of the ultrasonic cleaning cabinet, and special attention must be paid to avoid moisture. Never allow conductive liquids, such as water, to spill into the control cabinet through the ventilation openings, as this could cause severe damage to the circuit system and might even result in a complete failure of the device. Regularly inspect the ventilation ports to ensure they are unobstructed, and consider using protective waterproof covers for additional security.

Keep the Machine Clean and Turn Off Power When Not in Use

Cleanliness is essential for the efficient operation of the ultrasonic cleaning machine. After each use, be sure to clean the machine’s exterior and the tank, especially any residue left in the internal cleaning solution. When the machine is not in use, always turn off the power to avoid unnecessary wear on internal components. Also, periodically clean the control panel and display screen to prevent dust buildup from affecting performance.

Be Mindful of Continuous Working Time

The ultrasonic cleaning machine should not operate continuously for more than four hours. If prolonged operation is necessary, adjust the ultrasonic power control to the “0” position to stop the ultrasonic cleaning process. During this time, the cooling fan should continue running for at least 2 minutes to allow the system to cool down. This helps protect the ultrasonic generator and prevents overheating-related damage.

Ensure Proper Cooling After Shutdown

Before shutting down, always adjust the power knob to the zero position and let the machine run for an additional 3 to 6 minutes with the fan on to ensure adequate cooling. This procedure helps prevent internal components from overheating and prolongs the machine’s service life.

The quality of the cleaning solution directly affects cleaning performance, so it is essential to check the solution regularly. As cleaning time increases, contaminants in the solution can accumulate, reducing cleaning effectiveness. Therefore, it is important to filter or replace the solution as needed to maintain optimal cleaning conditions.

Regular Maintenance to Ensure Long-Term Stable Operation

To keep an ultrasonic washing machine in top working condition, regular maintenance is key. Below are several maintenance tasks that should be performed regularly to ensure the equipment’s long-term stability and efficiency:

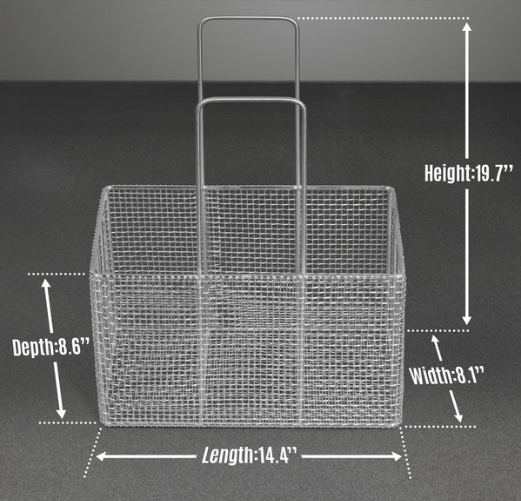

Check the Stability of the Cleaning Basket

Over time, the cleaning basket may experience weld separation or loosen due to vibration or impact. Regularly inspect and repair the basket as necessary to avoid malfunction or damage that could affect cleaning results.

Regularly Replace or Filter Cleaning Solutions

The piping system of the ultrasonic cleaning machine may suffer from wear and tear or loose connections, leading to water leakage. Inspect all pipe connections regularly and address any leakage promptly to prevent electrical system damage.

Clean the Tank to Extend Life and Reduce Chemical Consumption

The ultrasonic cleaning tank is prone to accumulating grease, dust, and other contaminants over time. Regularly clean the tank, especially to remove any oil residues, in order to extend the life of the tank and reduce the consumption of cleaning chemicals.

Inspect the Control Cabinet Wiring and Contacts

Monthly inspections of the control cabinet's electrical connections are essential. Pay special attention to the contactor wiring to ensure tight connections. Loose or corroded wiring can result in poor performance and potential electrical hazards.

Test the Residual Current Device (RCD)

The RCD is critical for ensuring safety during operation. Regularly test the RCD to ensure it functions correctly, providing protection in case of electrical faults.

Inspect for Leaking Pipes

Clean the Circuit Board

Dust buildup on the circuit board can impede cooling and cause malfunctions. Regularly clean the circuit board to prevent dust accumulation, ensuring efficient operation and heat dissipation.

Clean the Heating Elements

The heating elements on ultrasonic cleaning machines can accumulate scale and contaminants over time. Cleaning these elements not only improves heating efficiency but also extends their service life.

Conclusion

Proper use and regular maintenance of an ultrasonic cleaning machine are essential to ensuring its long-term reliability, efficiency, and cleaning effectiveness. By following the maintenance tips outlined above, users can keep their equipment in optimal condition, reduce the frequency of repairs, and prolong its service life. We hope this article provides valuable insights into ultrasonic cleaning machine maintenance and helps you keep your equipment running smoothly and efficiently.

Post time: Feb-24-2025