Traditional automated cleaning machines are highly precise but tend to be costly and have demanding requirements for matching equipment, which makes them unaffordable for many small and medium-sized enterprises. However, with technological advancements, more intelligent cleaning devices have emerged. For example, the single-tank oscillating ultrasonic cleaning machine, with its high-precision ultrasonic cleaning capabilities and advanced features like PLC intelligent control systems, has become a solution that meets the high standards for cleaning efficiency and quality in modern industrial production.

On the intelligent control front, the PLC system displays real-time cleaning status on an LCD screen, allowing operators to easily set cleaning parameters and ensure the process meets predefined standards. The intelligent scheduling feature also allows for pre-heating the cleaning solution, saving energy and improving cleaning efficiency. This automation and precise adjustment eliminate human errors, ensuring consistent and high-quality cleaning for each part.

Another key feature is the particulate matter recycling and filtration system. Oil and contaminants in the cleaning tank are extracted and recycled promptly, preventing pollutants from reattaching to components during cleaning. This not only improves the cleaning solution’s usage efficiency but also keeps the cleaning fluid clean, further ensuring stable and reliable cleaning results.The advantage of intelligent cleaning equipment lies not only in its precise control but also in its ability to meet a variety of production needs. The equipment can be configured with different cleaning functions such as pre-wash, rough wash, rinse, fine wash, and drying. It is also flexible enough to be disassembled and used independently, making it suitable for different production lines and processes. This versatility allows the cleaning equipment to adapt to a wide range of production environments and provides a more efficient solution for businesses.

Furthermore, intelligent cleaning devices ensure optimal cleaning conditions by precisely controlling the temperature, concentration, flow, and cleaning time of the cleaning solution. This guarantees that each part is cleaned thoroughly while minimizing material damage. The intelligent system automatically adjusts cleaning parameters based on the type of contaminants and the characteristics of the components, enhancing the cleaning accuracy and efficiency.

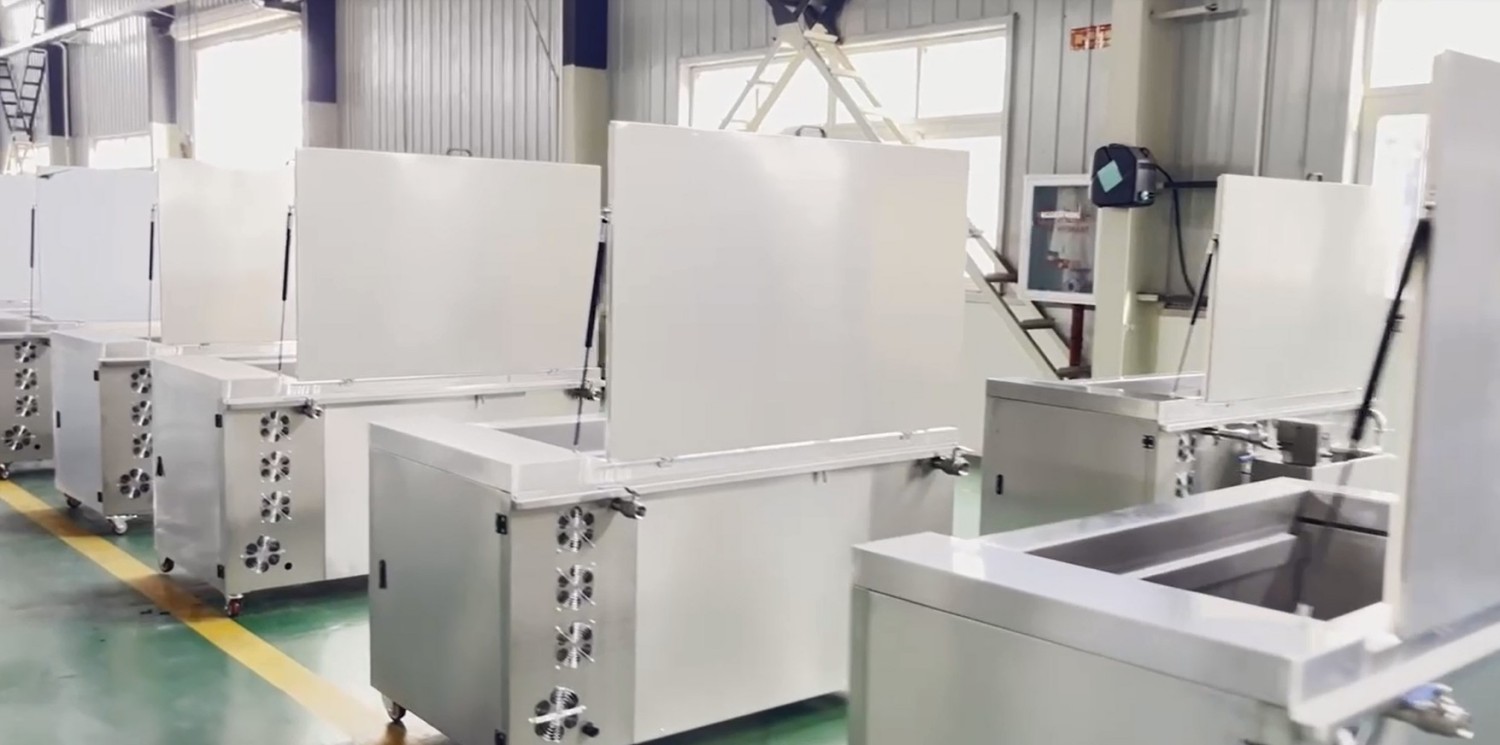

TENSE specializes in industrial production cleaning equipment; More than 20 years of cleaning experience in the industry. Solve customer cleaning problems.

Post time: Nov-22-2024